Laminating

Laminating

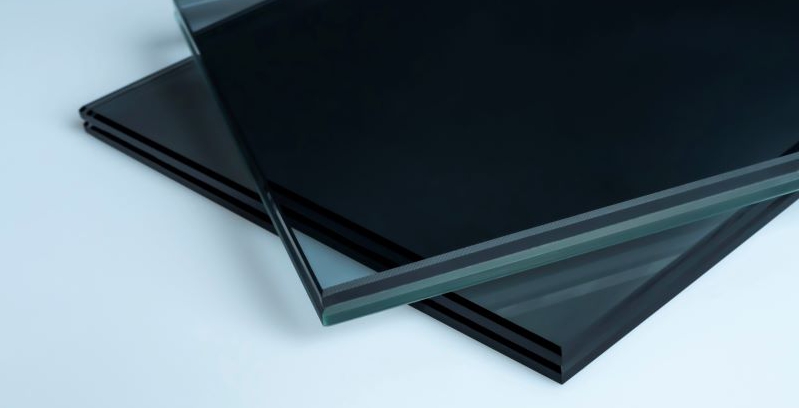

Glass lamination is a deliberate action to create safety glass by strengthening its structure. It involves bonding at least two panes of glass together using one or more special films placed between them. The entire process takes place in a specialist furnace which, in addition to high temperatures, also creates a vacuum which guarantees the permanent adhesion of the panes to the bonding film and the absence of air bubbles in the laminate. This process prevents the broken glass from fragmenting into pieces that may be threatening to life and health.

The solutions we use include lamination with:

- EVA film - its advantages include excellent transparency and durability, high tensile strength, UV protection, increased acoustic insulation, resistance to temperature changes, no discolouration or air bubbles, good adhesion to glass and low hygroscopicity, thanks to which it can be successfully used in particularly demanding conditions of high humidity of the air in coastal areas. Thanks to these properties, it can be used in both internal and external structures,

- PVB film - its advantages include high visible light transmission, UV protection, exceptional durability, and resistance to stress (e.g. use in point fixings), variety of material (including a wide colour spectrum and resistance to extreme weather conditions, such as hurricanes and violent storms). Thanks to its properties, it can be used in outdoor and indoor structures,

- Sentry Glass - is the new standard in glass strength. Unlike conventional laminated glass, it is 100 times stiffer and 5 times stronger, has a weight reduction of approximately 15%, increased transparency that is retained even after years of use, and resistance to moisture. It is used in windows, doors, skylights, facades, balustrades, glazings and partitions resistant to hurricanes, bomb blasts and ballistics; marine vessels, coastal regions, and areas with high concentrations of salt water.

Depending on the combination, i.e. the number and thickness of the individual glass panes and the film, laminated glass with different parameters and varying degrees of strength is obtained. These range from classic glass protecting against injuries to more durable protective, burglar-proof and hurricane- or ballistics-resistant variants.

In addition to the characteristics of safety glass, an important differentiator for laminated glass is its aesthetic value. We can use an unlimited number of patterns, graphics and even LED film or interactive film in laminates. What is important, many types of glass, including mirrors, can be combined in the lamination process.

As of 2022, we have introduced the modern technology of laminating glass with polycarbonate, which is distinguished by better parameters than in standard production, lightweight construction, lower product weight and a positive environmental effect with the simultaneous retention of technical parameters.

Maximum glass size: 3210 x 7000 mm (PVB), 3600 x 2000 mm (EVA)

Production order processing department

Dagmara Gliniecka

Sales Manager dagmara.gliniecka@wutkowski.com.pl

Natalia Kwiatkowska

Sales Specialist (Export) Mob: 453 056 525 natalia.kwiatkowska@wutkowski.com.pl

Magdalena Szmit

Senior Sales Specialist magdalena.szmit@wutkowski.com.pl

Izabela Warczak

Sales Specialist izabela.warczak@wutkowski.com.pl

Maria Karwasz

Senior Sales Specialist maria.karwasz@wutkowski.com.pl

Mateusz Glazer

Sales Specialist mateusz.glazer@wutkowski.com.pl

Zuzanna Welzant

Junior Sales Specialist zuzanna.welzant@wutkowski.com.pl

Weronika Drzewiecka

Junior Sales Specialist weronika.drzewiecka@wutkowski.com.pl

Adam Laskiewicz

Regional Sales Manager N-W adam.laskiewicz@wutkowski.com.pl

Piotr Nyc

Regional Sales Manager S-E piotr.nyc@wutkowski.com.pl